Gravure is the quiet workhorse behind everyday packaging, décor films, and glossy magazines. Analysts keep calling it resilient. One recent report sized gravure markets in the mid to upper billions this year with steady growth through the next decade.

Flexible packaging that uses rotogravure printing also shows solid year over year gains. That momentum comes from high-volume printing, long print runs, and the way gravure keeps color saturation and fine details locked in with consistent quality.

As someone who has been printing gravure for nearly 15 years, I can tell you that if you are a designer, a junior press tech, or a plant manager, I want you to leave with a clear picture you can use on the floor tomorrow.

You will find out how an engraved cylinder and its printing cells control ink transfer and the real tradeoffs that sit behind vibrant colors and print durability. You will also learn where rotogravure beats other methods and where it does not.

Here is the roadmap.

We start with fundamentals and key terms in plain language. We sort the types of cylinder engraving and when to pick each one. We walk the full process from copper plating to chrome plating to drying. We study applications and equipment. We close on quality control, cost, environment, and future trends you can plan for.

Now let’s dive in.

Gravure Printing Fundamentals

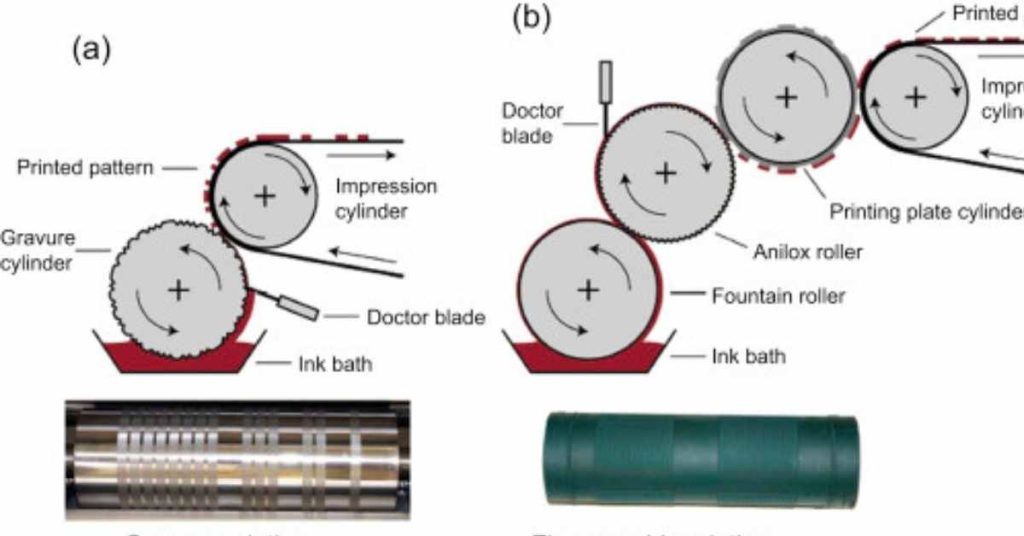

Gravure is an intaglio printing process. The image sits as tiny recessed cells in a metal cylinder. Ink fills those cells. The press squeezes paper or film against the cylinder and pulls the ink out. That is why people also call it rotogravure printing. The cylinder is the image carrier and the cells decide how much ink transfers to the substrate.

How Does Gravure Differ

Relief printing put ink on raised areas. Intaglio printing did the opposite and stored ink below the surface. Early banknotes proved how much detail intaglio could hold.

Industry later wrapped that idea around a rotating cylinder. The result was a machine that could run long print runs at high printing speed with registration accuracy that stayed stable. That lead to gravure printing.

Check my post if you want to know more the beginner friendly ways to identify gravure printing.

Key Parts on Press

The main parts of a gravure press are easy to name but tough to master. The engraved cylinder is the image carrier. It is covered in microscopic printing cells that hold ink.

A doctor blade wipes the surface clean so only the recessed cells carry ink. The impression roller presses the substrate against the cylinder, and the nip between them is where the ink transfer happens.

Two numbers matter most for each cell: cell depth and cell opening. Together, they decide how much ink moves to the substrate and how strong your ink density and color saturation look.

Beginner Terms You Will Hear Daily

- Cylinder engraving is the way we create the cells, either with a stylus, laser, or chemical etch.

- Printing cells are the tiny recesses that store ink until transfer.

- Ink transfer is the handoff from cell to substrate.

- Image carrier is simply the engraved cylinder.

- Press conditions mean all the factors in play: speed, nip pressure, ink temperature, dryer settings, and web tension.

- Substrate transfer describes how cleanly the ink leaves the cells and bonds to the paper, foil, or film.

Why Gravure Shines

Gravure printing shines because of three very specific strengths:

- Consistency on long runs. Once the cylinder is engraved, every impression looks nearly identical. That stability makes gravure ideal for high-volume printing where quality must stay locked over millions of copies.

- Detail and tone control. Cell depth and opening let you carry both heavy solids and delicate highlights on the same cylinder. That is why gravure delivers vibrant colors and fine details in one pass.

- Durability of the image carrier. The engraved cylinder, especially when chrome plated, lasts for long print runs without losing registration accuracy or color balance.

These are not abstract claims. They are the real reasons why gravure is the backbone of packaging, décor, and magazine work. It shines when you need vibrant colors, consistent quality, and print durability at industrial scale where other processes often fall short.

Types and Classifications

Gravure printing is not one single method. The way the engraved cylinder is prepared changes everything from how your printing cells hold ink to how stable your ink transfer looks during a long run. Here are the main types and how they compare.

Engraved vs. Etched Gravure

- Etched Gravure

- Uses chemical etching to bite recessed cells into a copper-plated cylinder.

- Masking controls where the acid eats and how deep the cells go.

- Ink density depends on how consistent the etch is across the surface.

- Great for smooth tonal ranges, gray ramps, and fine work.

- Engraved Gravure

- Cells are cut directly into the copper surface using a diamond stylus, laser, or electronic engraver.

- Depth, opening, and wall angle are controlled by the engraving head.

- Delivers repeatable cells across the entire cylinder, making it ideal for high-volume printing.

Manual, Mechanical, and Electronic Engraving Methods

- Manual Engraving

- Done by hand with tools on a copper surface.

- Extremely slow, used today only for security or artistic intaglio printing.

- Produces unique character but not suited for long print runs.

- Mechanical Engraving

- Uses a diamond stylus that pulses while the cylinder spins.

- Creates uniform cells at set angles and depths.

- Works well for packaging or décor jobs where stability is more important than highlight smoothness.

- Electronic Engraving

- The modern standard in rotogravure printing.

- Frequency, angle, and depth are adjusted digitally on the fly.

- Lets highlight cells carry less ink and shadow cells carry more.

- Ensures vibrant colors and consistent quality even at high printing speed.

- Laser Engraving

- A laser ablates the copper surface to form cells with very steep walls.

- High repeatability and precision for long print runs.

- Especially effective for flexible packaging and coatings that require heavy laydown.

- Can produce special cell geometries for metallic inks or dense whites.

Application-Specific Selection Criteria

How do you choose the right cylinder engraving method? Think in terms of the job, not the label.

- Skin tones and fine type → Use etched or laser gravure for clean tonal transitions.

- Wide jobs at maximum printing speed → Choose electronic engraving for stable ink density.

- Heavy solids or metallic inks → Go with laser or mechanical engraving with deeper cell depth.

- Porous paper jobs → Coarse, deep cells to deliver more ink without starving coverage.

- Thin films that block easily → Shallow cells for fast drying and reduced risk of blocking.

Examples from real jobs I have seen:

- A snack pouch with dense solids and reverse type prints best with electronic or laser-engraved cylinders tuned for exact cell depth.

- A décor laminate with long woodgrain repeats benefits from stylus engraving at a consistent angle for stability.

- A magazine cover with skin tones calls for a hybrid approach that protects highlights but holds shadow weight.

Technical Process Deep-Dive

After years of running gravure presses, I always explain the process in five main stages. Each stage has checkpoints that protect print quality and keep the run stable.

Cylinder Preparation

Before anything else, the image carrier has to be right.

- Start with a steel base, then build it up with copper plating to the target thickness.

- Polish the copper surface to a mirror finish so the cylinder engraving head has no interruptions.

- Check cylinder runout, because even a small wobble here can ruin registration accuracy later.

- After engraving, apply a thin layer of chrome plating to protect the copper. Chrome also gives the doctor blade a consistent ride.

Cylinder Engraving

How you engrave the printing cells decides most of the final print.

- The engraving system uses a map that controls cell depth, cell opening, and screen angle.

- Shallow cells carry less ink for highlights while deeper cells hold more ink for shadows.

- A microscope check confirms the geometry and screen count.

- Run a quick band test on the press to verify that ink density is stable across the repeat.

Inking and Doctoring

This stage looks simple, but it is where many problems start.

- The engraved cylinder is flooded with solvent-based inks.

- The doctor blade wipes the surface clean, leaving ink only in the recessed cells.

- Blade angle, material, and pressure control streaks, haze, and pickup.

- Ink temperature affects flow. Heat makes ink thinner and shifts laydown, so you keep it stable.

Ink Transfer in the Nip

The nip is where the substrate meets the ink.

- The impression roller pushes the paper, film, or foil into the engraved cylinder.

- Web tension, nip pressure, and substrate surface energy control how much ink leaves the cells.

- Substrate transfer has to be consistent or you get variation in color saturation and solids.

- On-press spectro readings confirm target ink density and registration.

Drying and Finishing

Once the ink is on the substrate, it needs to be stable before the next station.

- High-volume dryers remove solvent between colors.

- You want the ink dry enough to touch but not so dry that the next layer will not bond.

- At the end, chill rollers flatten the web before rewind.

- Retain a sample at packout for durability checks like rub resistance and tape pull.

Quality Control at Every Stage

Each step has its own checkpoint.

- After copper plating, confirm thickness.

- After engraving, measure cell depth and opening.

- During printing, monitor ink viscosity, web tension, press conditions, and cylinder temperature.

- At the end, check print durability with rub and adhesion tests.

If you build these checks into your workflow, gravure becomes one of the most stable and reliable printing processes for high-volume printing and long print runs.

Applications and Use Cases

Most of my daily work is flexible packaging. Snack pouches, retort films, labels on shrink sleeves, and cold seal coatings all love gravure. The process hits long print runs with stable ink density and rich solids.

The packaging segment using rotogravure printing is growing along with consumer goods and food packaging. Market studies show steady gains for gravure and gravure services driven by packaging and decorative films.

Publishing is quieter than it used to be yet still active in certain regions. Catalogs and high end magazines pick gravure when they need consistent quality over millions of impressions.

Security and specialty work use gravure for coatings and for features that demand fine details. Banknote intaglio is a different branch of intaglio printing but the idea is the same. Deep relief gives tactile cues and print durability that help with verification.

Decorative films and laminates are a natural fit. Woodgrain, marble, and textile looks need smooth gradients and repeat control. Gravure makes those textures feel real even on plastic film.

When I choose a method I match the job. If the customer wants vibrant colors on clear film with a heavy white underlayer, gravure makes the work look premium. If the customer wants short runs with fast swaps, I consider other processes.

Equipment and Technology

A modern rotogravure line starts with unwind and infeed that keep web tension steady. Web guides correct edge wander. The print unit has an ink pan, an engraved cylinder, a doctor blade in a holder, and an impression roller. Dryers sit after each unit. A chill roll stack cools the web before rewind.

Today the line is covered in sensors. Closed loop viscosity control keeps ink transfer stable as solvent flashes. Register cameras watch marks and nudge drives. Color instruments read patches and hold targets. Thermal sensors watch dryer performance so you do not cook a thin film.

Digital integration is real. Prepress links cylinder engraving data to press recipes. Your press can load cell depth curves and set press conditions with a single job file.

Maintenance systems watch bearing temps and blade life and flag trends. Many shops now build digital twins of job setups so a restart does not start from zero.

Specs That Matter on the Floor

When you have been around gravure presses for years, you stop caring about glossy brochures and start caring about what keeps the run stable day after day. These are the things that matter most.

Stable Printing Speed

A good press must hold quality at your target printing speed without drifting. If the engraved cylinder cannot maintain consistent ink density when you push the line, you will bleed money on wasted substrate and downtime.

Impression Roller Control

The impression roller is not just a support roller. It sets the nip pressure that drives ink transfer. On wide webs, you need even pressure across the entire width. If the roller wears unevenly, you will see banding and solids that break down long before the run is done.

Cylinder Carriage and Swapping

Jobs today change faster than they did ten years ago. A cylinder carriage that swaps cylinders quickly and locks them precisely is the difference between making profit or losing it. If you waste an hour on every changeover, the press is earning nothing.

Dryer Performance

Dryers have to hit the right exit temperature with room to spare, even on humid days when solvent load is heavy. Weak dryers force you to slow the press, and that ruins the whole point of gravure’s high-volume advantage. Consistent drying also protects registration accuracy across multiple stations.

Rewind Quality

At the end of the line, the rewind must build tight, even rolls. If rolls are baggy or uneven, everything you did upstream can be lost. A good rewind keeps tension balanced and preserves the integrity of your print until it is slit, laminated, or shipped.

Quality Control and Troubleshooting

I have learned that the quality of a gravure job is never an accident. It is the result of habits, checkpoints, and knowing how to react when the print starts drifting. Here is how I break it down.

Setup Checks Before You Run

Before the first impression comes off the press, every part of the system must be tuned.

- Calibrate the spectrophotometer and densitometer so measurements are trustworthy.

- Load target ink density for each color into the control system.

- Confirm cylinder runout and check engraved cylinder TIR.

- Verify impression roller hardness and roundness.

- Inspect doctor blade setup, angle, and pressure.

- Check web tension and adjust press conditions for the substrate in use.

- Pull a first-off proof and record all baseline numbers.

Common Defects and Fast Fixes

Even with the best preparation, problems appear. The key is knowing their source.

- Haze across the image

- Often weak doctor blade contact or chrome glaze.

- Clean the cylinder and reset blade pressure.

- Light streaks every rotation

- Usually dried ink buildup on the doctor blade edge.

- Flip or change the blade.

- Dark bands in solids

- Worn impression roller zones.

- Rotate or replace the roller.

- Specks or pinholes

- Dust, poor filtration, or solvent pop.

- Improve filtration, stabilize ink temperature, and adjust first-station dryer.

- Weak solids

- Shallow cell depth or ink too thin.

- Raise viscosity and recheck ink transfer.

- Poor registration accuracy

- Web tension drift or heat load in the web.

- Adjust tension control and balance dryer airflow.

Measurement and Documentation

Numbers protect profit. Following are the things that I constantly measure and compare against benchmarks that I have created for myself.

- Monitor ink density, delta E, gloss, and mottle.

- Track missing dots with magnification.

- Run rub resistance and tape adhesion tests for print durability.

- Keep a control chart for long jobs so drift is spotted early.

Preventive Maintenance

Most defects can be prevented if the press is maintained like production equipment rather than an afterthought.

Here are the things that I regularly do so that the process is always smooth and there are no unpleasant surprises.

- Replace doctor blades on schedule, not just when they fail.

- Clean and store engraved cylinders with care.

- Check impression roller hardness regularly.

- Balance airflow in dryers for even drying.

- Calibrate sensors and instruments on a fixed schedule.

A shop that treats preventive maintenance as part of production time always ends up printing faster and with fewer rejects.

Cost Analysis and ROI

Gravure looks expensive at first and then pays you back when the run is long. The first big cost is cylinder making. Copper plating, cylinder engraving, and chrome plating take time and money. You also pay for the press, the dryers, and ventilation. Solvent-based inks and energy add to the bill.

Break even shifts with run length. Short art runs lean toward other methods. Long runs flip the math because the cylinder cost spreads over many impressions and the press runs fast with few stops.

I often build a simple model with three inputs. Gravure wins when the job is stable and will repeat.

- Number of colors

- Total impressions

- Changeover time

Recurring costs are real. Cylinders will wear off and need rechrome.

Doctor blades, solvents, filters, and energy sit on every invoice and shoot up the costs. Blankets do not live on gravure the way they do on offset, yet impression rollers and sleeves do age. Relief methods save you cylinders, but often give up speed or color weight on film.

When starting out, always compare with alternatives by total cost per thousand prints. Add waste, rework, and color drift to the equation. Gravure holds registration accuracy and color once it is tuned.

Your ROI comes from uptime, speed, and repeat orders that reuse the same image carrier.

Environmental Considerations

One of the toughest conversations around gravure printing is the use of solvent-based inks. These inks are chosen because they dry quickly and bond well to films, but they also create volatile organic compound emissions that have to be controlled carefully.

To address this, most professional printers operate with enclosed systems that capture vapors before they escape, moving them through recovery units or thermal oxidizers.

Regulators often point to toluene as a common solvent in rotogravure printing, and they recommend mitigation through activated carbon systems, incineration, or solvent recovery.

Air quality, however, is only one part of the picture. Sustainability in gravure also includes how long an engraved cylinder lasts and how it is handled at the end of its life.

Many printers refurbish old cylinders by stripping and reclaiming copper, which reduces both cost and waste. Used doctor blades, solvent residues, and leftover ink sludges need careful disposal to avoid contamination.

Over the past decade, suppliers have also moved toward lower-aromatic blends and limited lines of water-reducible inks for certain jobs. Shops that cannot make that switch still improve their footprint by investing in better enclosures, ventilation, and housekeeping to cut down on fugitive losses.

Another area where gravure printing intersects with sustainability is the circular economy push from brand owners. Packaging clients now demand substrates that are easier to recycle, such as mono-material films. Gravure can print on these films successfully, but it requires careful adjustment of cell depth and ink rheology to balance adhesion with fast drying.

The reality is that no single change makes a gravure plant “green.” Instead, progress comes from dozens of smaller steps, such as leak checks, solvent balance control, cylinder recycling, and optimized drying, that together create a measurable impact.

Future Trends

The future of gravure printing is being shaped by digital integration and smarter automation, and the changes are visible right on the press floor. Job files no longer carry only artwork. They now include cylinder engraving curves, target ink density values, and registration settings that can be transferred directly into the press software. This allows the press to load recipes automatically, which reduces setup time and keeps runs consistent.

At the same time, vision systems watch every repeat in real time and flag any defect before it spreads across the roll. This shift is what people call Industry 4.0, and gravure printing has started to embrace it.

Engraving technology itself is also advancing. Direct laser systems can now cut cleaner printing cells with shapes that hold metallic inks or coatings more effectively.

Electronic engraving has improved highlight control, which reduces moiré patterns and protects delicate tonal areas that used to be difficult to manage. These innovations help gravure presses maintain fine detail at high printing speed while still delivering vibrant colors and consistent quality.

Automation continues to expand into areas that used to rely on operator judgment. Automatic washup systems, auto doctor blade setup, viscosity control, and register correction are now common on modern presses.

Plants are even tying energy meters into press conditions to lower gas usage in dryers without compromising drying performance. This improves efficiency while reducing costs.

Industry reports point to steady growth in gravure printing machines and inks, especially as demand for flexible packaging increases. Brand owners continue to ask for consistent quality, durable prints, and long-run efficiency, which makes gravure attractive compared to other processes.

For printers, the message is clear. Success in the coming years will depend on mastering the craft at the level of the printing cell while also learning to read and use the data that automation provides. Gravure has always rewarded people who can feel the ink, and now it rewards those who can read the numbers as well.

Final Words For Those Who Are Thinking About Gravure Printing

If you are just starting out with gravure printing, remember that it is an intaglio printing process built around an engraved cylinder filled with thousands of tiny printing cells.

Each step, from copper plating to ink transfer and drying, has a reason and a rhythm. Gravure shines because it delivers consistent quality, vibrant colors, and long print runs that other methods struggle to match. As a beginner, focus on learning the basics of the doctor blade, the impression roller, and how cell depth controls ink density. Once you master these fundamentals, the rest will fall into place.

Also, gravure can be heavy on the pocket initially. But economies of scale and repeat orders can make it profitable if you’re someone who can take the hit while starting out.

References:

https://www.verifiedmarketreports.com/product/rotogravure-printing-in-flexible-packaging-market/

https://www.gi-de.com/en/currency-technology/banknote-solutions/banknote-security-technology/printed-security-features

https://banknoteinfo.net/security-features/intaglio-printing/

https://www.gi-de.com/en/currency-technology/banknote-solutions/banknote-security-technology/printed-security-features

https://www3.epa.gov/ttnchie1/ap42/ch04/final/c4s09-2.pdf

https://pdfs.semanticscholar.org/f3e5/51fe52759d17da7925a3572ece5a95d9b329.pdf